Biofouling goes Undetected

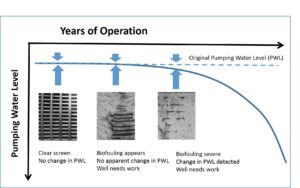

I had the pleasure of attending Michael Schneiders’ presentation at our annual convention this year. Michael’s talk was predominantly about biofouling problems in wells. He mentioned that biological growth can establish a solid foothold on a well screen before the well shows signs of impaired performance. That is, before the pumping water level (PWL) starts creeping downwards.

Regularly measuring a well’s PWL is a common means of tracking well performance over time, assuming that the pumping rate and static water level stay about the same. Monitoring of the PWL is made possible by a sounding tube installed inside the well. These are typically one inch in diameter and are usually installed from the top of the pump up to the well cap. In my opinion, regular installation of sounding tubes is a mark of professionalism and an acknowledgement that the well will need to be monitored after the pump is up and running.

Typically, well rehabilitation work is undertaken when the PWL drops too close to the pump intake. However, Michael’s research challenges the assumption that a steady PWL means that a well screen is in good condition, when in actual fact biofouling may be beginning to take hold. For this reason, a down-hole video survey of the well screen is a worthwhile investment. This is illustrated in Figure 1. For this example, rehabilitating the well sooner, when the screen was partially obstructed, would have been easier and less costly than rehabilitating the well later, when the screen was almost fully obstructed and a drop in PWL was observed.

A down-hole video survey of a well can be completed at little extra cost during a pump change out. If the well screen is not looking good, other information, such as microbiological and chemical analyses of a well water sample, may help determine the source and degree of the problem, and the opportune time to address it.

Well Specialists rely on good information to help make informed decisions on well problems. Well owners and operators can do their part by keeping records of: static water levels, pumping water levels, water quality tests (including any unusual color or odour), and any video clips of the interior of the well. Original measurements taken when the well is first brought on-line are very important and constitute ‘basemarks’ against which future measurements can be compared. These need to be documented and easy to access in the well owner’s files.

With proper ‘basemarks’ in place, well owners can rely on their data to decide when to schedule rehabilitation work, rather than wait for a pump failure or noticeable drop in well performance. Scheduled maintenance activities performed at convenient times (e.g. during the wet winter season for irrigation wells) are less costly and more efficient than a patchwork of rush maintenance activities performed at inconvenient times. Furthermore, repeat, regular maintenance has the potential to extend the operating life of your well.

Our improved understanding of biological growth in wells builds the argument for more routine monitoring of a variety of parameters besides PWL. Pump installers are typically the ‘first responders’ when there are problems with the well, and can help well owners establish a ‘predictive maintenance’ program. For this, a quality down-hole camera is a worthwhile investment. Wells are becoming older and need service work, and we all have a part to play in getting the most out of our water well asset.